How to Accurately Predict Structural Weights... Science!

No matter how good a model aircraft design is, it will not fly well if it's too heavy or balanced improperly. There's always a bit of trial and error in any new design, but there are a few things you can predict, in regard to weight and balance.

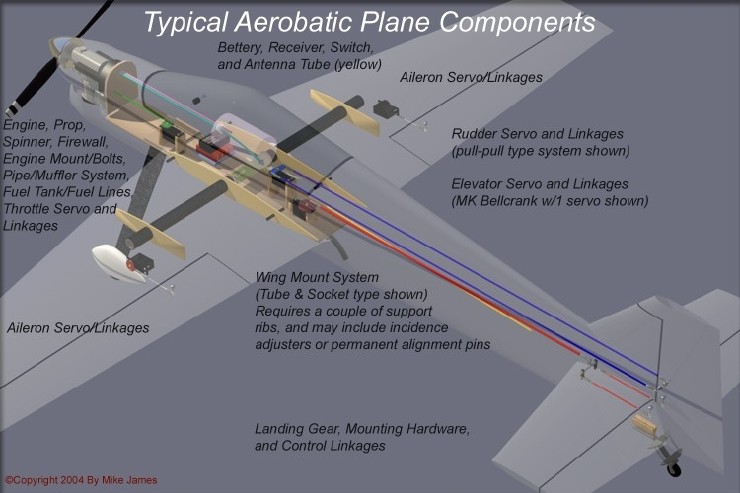

Certain components of your design weight are fixed, and can be very precisely predicted. These include the weight of your engine and mount, fuel tank and plumbing, radio receiver and battery, servos, pushrods, and the associated foam, screws, etc., used to hold everything in place. It pays to weigh these items, since you only have to do it once, and then have a reference for the future. Remember that these things go in the plane, regardless of other design considerations. As an example, take a look at the components in a typical Pattern-type aerobatic plane. In the case of a plane like this, the mandatory internal parts can easily amount to half or more of the total weight.

Structural weights are a bit trickier to predict, but we can get close. I do this during the design phase, before drawings are finalized, so that I might change the scale, or type of materials used, if needed. If you are using a CAD program and/or making drawings, you have a good idea of how many square inches each part is, or you can easily figure it out.

One day I got out a calculator and did a little math, and came up with some "magic" numbers you can use for balsa, ply, fiberglass, and foam. First a few prerequisites that will help you prove that these figures are true:

1 square foot =144 square inches

1 square yard=1296 square inches

1 cubic foot=1728 cubic inches

The "magic" numbers are in BOLD, below.

The weight of any material, including balsa, ply, and foam is .009259 X Density, per cubic inch.

For example, a 4 inch X 36 inch sheet (144 square inches) of 1/16th balsa, (.0625 inches thick) at 6 pound density, is:

(144 X .009259 X 6) X .0625 = .49 ounces

Take a 500 square inch sport wing. That's 1000 square inches total, for covering purposes, since we do both sides.

At 4 pound density, the foam cores will weigh approximately (depending on the airfoil) 6 to 8 ounces (total for both)

At 6 pound density, the balsa sheeting will weigh approximately 3.47 ounces.

Figure approximately .003 ounces of resin per square inch. to attach the sheeting, so the resin will weigh about 3 ounces.

Add to this the leading and trailing edges, landing gear and/or servo mounts, and final covering, and you can get very close estimates!

The weight of plywood (at 12 pound density) is .1111111 ounces per cubic inch

MonoKote opaques (without backing material) weigh 1.8 ounces per square yard. (Some others colors weigh even less.)

Fiberglass layups (using the same weight of resin as cloth, i.e. 1 ounce of resin per 1 ounce of cloth, which is the standard) weigh as follows:

(The numbers below represent the weight of the cloth... i.e. a "2/4" layup is one layer each of 2 ounce and 4 ounce cloth) Obviously then, a quick estimate of a glass layup is simply to add the two "weight" numbers of the cloth, then double it for the resin. See below for some examples.

> A 2/4 layup weighs 12 ounces per square yard, or .0092592 ounces per square inch.

> A 2/6 layup weighs 16 ounces per square yard, or .0123456 ounces per square inch.

> A 4/6 layup weighs 20 ounces per square yard, or .0154321 ounces per square inch.

Wings and tail surfaces are relatively easy to predict, due to the ease of measuring them. It's a little more tricky to figure out how many square inches are in you curvy fuselage or engine nacelle. Still, you can use your side and top views to get pretty close, and with repetition, you'll develop your own formula. If you use the same construction methods all the time, and build similar shapes all the time, then you can even figure out how many "ounces per inch" (speaking of length) your typical fuselages are.