The 1/3rd Scale Berkut-Long EZ

My newer (2010) 3D model of this design is available on www.mikejamesmedia.com

Design Overview, and a little history

If you've read about the Fusco Fiaso, you know that this project is completely dead, as far as any kit production goes. Still, after thinking about it for a while, I realized that there were things about the design and construction of the model (plugs, molds, airfoils, etc.) that modelers might be interested in. So, I've decided to re-publish the article here, and share some of the information with you. This 4-page article shows the development of the whole kit, but I've created separate articles on making the cowling and the canopy, so you can view them separately if you like.

|

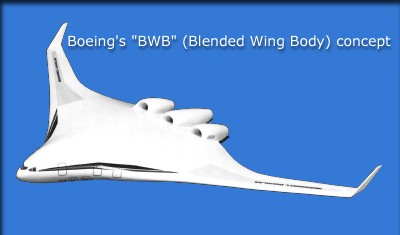

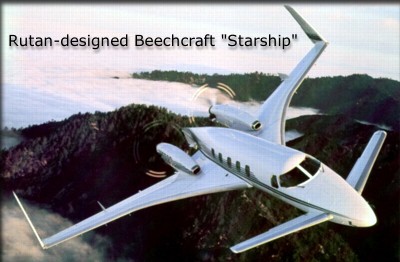

Burt Rutan developed the Long EZ for homebuilders back in 1974, and it remains a remarkable design to this day. It's largely made of composites, (foam and fiberglass) and is light, fast, and efficient. Many aircraft have now been designed using variations on the planform. Take a look at a few other designs which all bear similarities to the Long EZ. ...There are many others. |

|

|

|

|

Long EZ owners have flown their planes around the world. The U.S. Army has studied it, for use in recon and other missions. Various companies have expanded on the design by building a cabin for more occupants. A Long EZ is currently being used to test liquid-fueled, throttleable rocket engines, piloted by Dick Rutan. One designer has converted his Long EZ to a large ducted fan system. More variations will surely appear. Renaissance Composites, and later Berkut Engineering, made some remarkable improvements to the plane. The Berkut boasts an impressive 18 to 1 glide ratio, rivaling some gliders. Although the actual Berkut Engineering kits are no longer being reproduced, I've included their story, and some statistics to show the enhanced performance. I thought that modelers would appreciate these improved characteristics in the 33% model, as well.

(The following text is from Berkut Engineering)Birth of Berkut

In 1989, construction began on the prototype bird, now called the Berkut. The model of the fuselage built in 1987 was 12" longer, 3.5" wider, and provided 4" more headroom than the Long EZ. These features were retained in the prototype Berkut. This airplane would emerge with fully retractable gear, designed by Shirl Dickey, designer of the ERacer. Ronneberg acquired the rights to use Shirl's gear in the prototype and future Berkut kits and now produces the gear himself after Dickey stopped production. The prototype Berkut utilized a Lycoming IO-360 180-hp engine bumped up to 205 hp. Light Speed Engineering's Klaus Savier designed the electronic ignition. As a side note, Berkut builder Glenn Waters installed a stock 180-hp Lycoming in his Berkut 360 as a requirement of the Popular Flying Association (PFA- kind of a cross between our EAA and FAA). With this stock engine, Glenn is seeing speeds well in excess of those in the prototype with the bumped-up engine. Glenn has a very clean, beautiful airplane. The Berkut differs from the EZ in a number of other ways. The canopy of the Long EZ is one piece whereas the Berkut canopy is two pieces, a canopy for each person much like a fighter jet. This was incorporated to eliminate the effect of shrinkage of a canopy this size at colder temperatures, affecting the fit and seal of the canopy. The Berkut ailerons are 6" longer than on an EZ and have a 3/4" larger chord at upper surface the hinge line and 7/8" larger chord on the lower surface. The lower winglets have been eliminated by incorporating them into the wing on the Berkut. The strakes (the triangle portions between the fuselage and wing) have a convex upper surface instead of the flat surface found on the EZ. The Berkut also makes use of carbon fiber in the design. Carbon fiber is found in the canopy frame, wing skins and spar caps, main spar caps, and canard skins and spar caps, longerons and cowls. Carbon fiber was chosen because it is four times stiffer and one-and-one-half times stronger than fiberglass by weight. The use of carbon fiber in the Berkut prevents unwanted torsional flexing in the wing, making for a much more rigid structure with no weight penalties. This, combined with the larger ailerons, also makes for a roll rate double that of a Long EZ. The prototype Berkut was completed in the summer of 1991 and flown to Oshkosh. The reception was outstanding but Ronneberg was not ready to sell kits just yet. He used the next year to acquire financing, tooling, and materials necessary for producing kits, as well as writing a construction manual. At Oshkosh 1992, orders were taken for kits and deliveries began in January of 1993.

Races, Shows and a 540The Berkut has had its share of race wins beginning with the prototype in July of 1992. Berkut placed first in the Jackpot Nevada EZ Bash, coming in at 240.96 mph. In 1993 at Sun n Fun, the Berkut finished first in the Class 2A race, averaging 247.19 mph from a standing start. And finally, the prototype Berkut finished its racing career where it all began, in Jackpot, Nevada placing first once again in the Unlimited Class with a speed of 245.45 mph. It also won Jackpot Races in 1996, '97 and '98. In addition to races, Berkut entered the exciting world of air shows. The Berkut made its air show debut in Santa Ynez in the Spring of 1993. At the controls was Commander Rick Fessenden, company test pilot and ex-military F-18 pilot. Some of the most spectacular air show performances ever seen were performed by Rick who put the aircraft through its paces. Rick's performance may be seen on the Berkut video. The Berkut in air shows ended in August of 1995, when during a sustained 9G turn, Fessenden apparently experienced G-loc and did not recover. The aviation community lost a great man. The first IO-540 was proposed for a Berkut in 1996 by a builder. It required the construction of a new engine mount, engine mount ears and new cowls by Ronneberg. This led to the IO-540 being offered as an option for the Berkut. Shortly thereafter an IO-540 was installed by Ronneberg and Misha Kasyan, whose airplane has graced the covers of many magazines in its Air Force Flight Test neon orange paint. Subsequently the IO-540 became a more popular installation on the Berkut and is now offered as the standard engine configuration, though the IO-360 is still an option for those not needing quite as much horsepower. Berkut flew its first Reno Air Race in 1999 and finished second in the Silver Class behind a fast Glasair III and ahead of six other Glasairs, with a winning speed of 261.7 mph. The airplane was equipped with a 308-hp Lycoming IO-540 built by Ron Monson of Performance Aero Engines and turned a Klaus Savier fixed-pitch prop. Dave Ronneberg piloted the aircraft to its outstanding finish and found Berkut's excellent, unrestricted visibility to be a significant advantage throughout the race.

An All-molded AirplaneThe late 1990's and early 2000 have seen improvements to the Berkut kit and components. A few highlights include redesigned landing gear constructed in-house that is also used in Shirl Dickey's ERacer. The biggest accomplishment has been the completion of tooling for molded canard and wings with winglets attached. The only foam in the airplane are the canard and wing tips. This combination not only comes in weighing less than a conventional foam wing, but stronger and faster to build. The airplane now incorporates over 100 molded components and has the best fit and finish found in any airplane in the kit industry.

Performance comparison of original Rutan Long EZ and Berkut variant

| Item | Original Long EZ | Berkut (260 horsepower) |

|---|---|---|

| Landing Gear |

Fixed Main/Nose Retract |

Tricycle Retracts |

| Useful Load |

830 pounds |

960 Pounds |

| Climb Rate - Gross Weight |

1500 Feet per minute |

2000 Feet per minute |

| Cruise Speed at 8000 ft. - 75% power |

140 Knots |

237 Knots |

| Maximum Structural Speed |

220 MPH |

350 MPH |

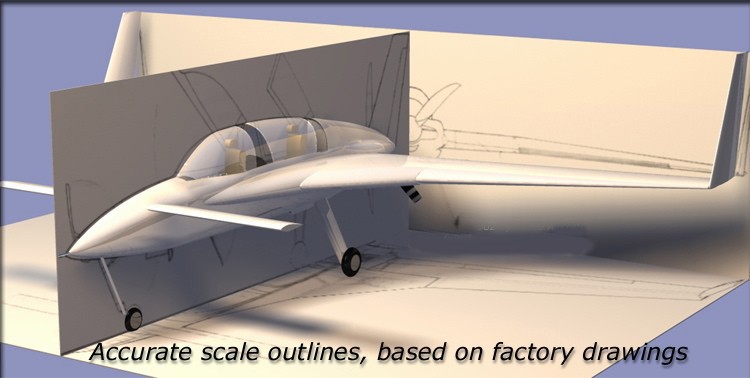

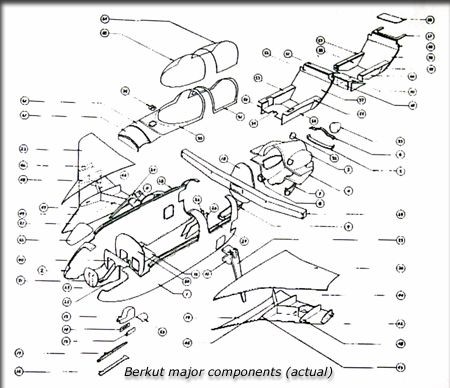

As you can see, there are many differences, some subtle, between the original Long EZ and the Berkut. The aileron change, winglet change, and canopy change were all incorporated in the kit. The surface smoothness improvements of the Berkut were achieved in the kit, by constructing the entire fuselage and inboard wing panels from molded composites. The altered inboard strake airfoil change is incorporated too. In fact, I used actual Berkut Engineering drawings, graciously supplied by Berkut Engineering, as the primary source material for the kit outlines. All dimensions are accurate, aside from some changes I had to make in the canard, for the plane to be able to fly, and the retractable main gear. (More on that later) The early Berkut models had fixed gear, just like the Long EZ, so a perfectly accurate Berkut could have been created with this kit.

Below are some (actual) Berkut photos from the Reno Air Races, builders photos, interiors, etc..

|

|

|

|

|

|

|

|

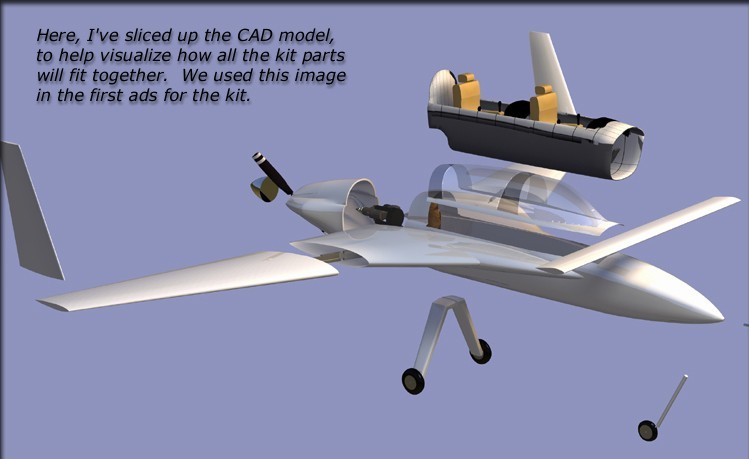

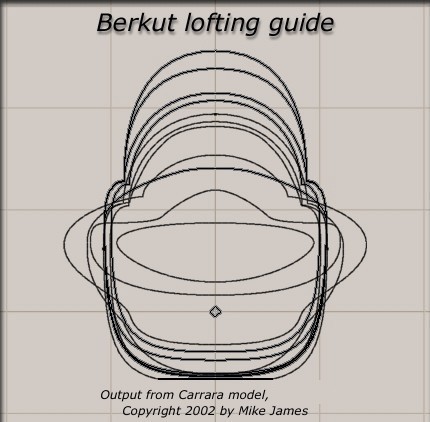

With the research completed, I created a CAD model, to help me visualize how the kit should be made.

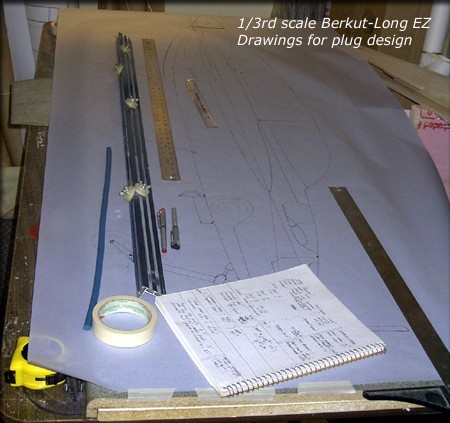

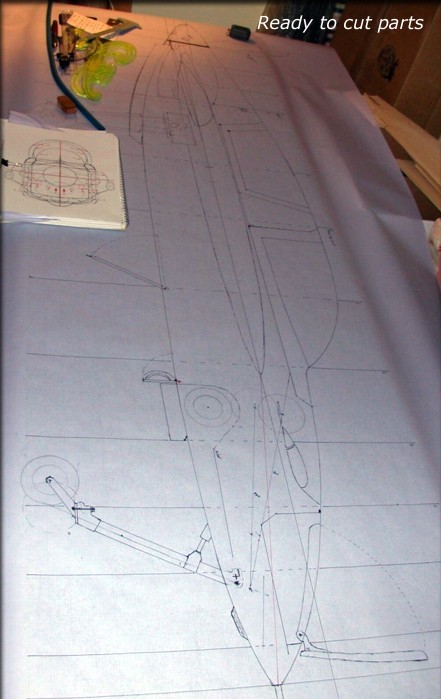

With the CAD model finished, I started on the drawings that would be used to design the plugs.

Some Berkut builders took great pains to squeeze every ounce of performance out of their planes. One option, from Light Speed Engineering, was this drag-reducing spinner, and custom composite prop. Since I designed the kit to use readily availble parts from hobby shops, the cowling shape wass optimized for a 4-inch diameter spinner.

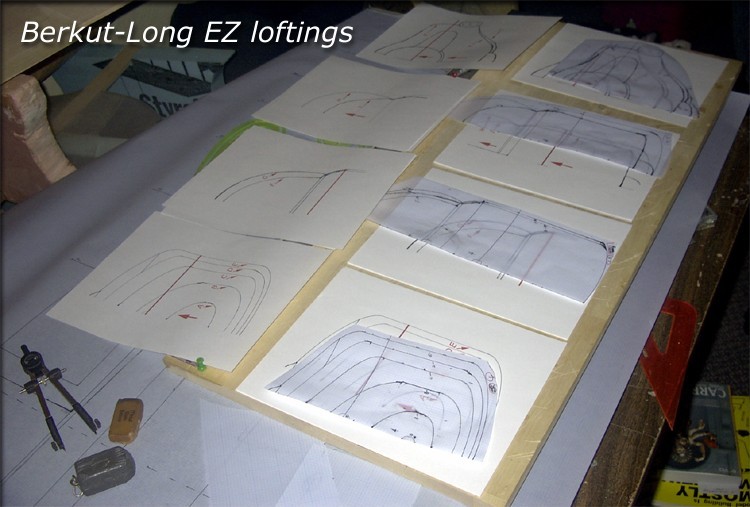

Here are some "guidline" loftings from my 3D software, "Carrara Studio". These, combined with the factory drawings and a great number of photos insured the accuracy of the plugs. I was lucky to find a very nicely done Long EZ locally to photograph, too.

The plans were then checked against the Carrara renderings, and loftings (cross-sections) were created for the plugs.

Factory drawings such as this one help in the design of the model components.

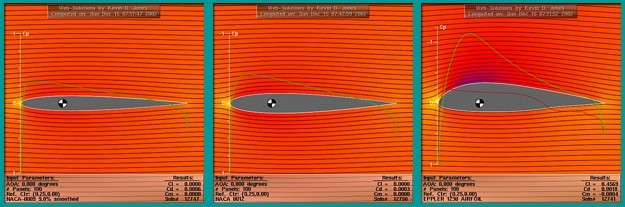

After researching the airfoils used on the actual Berkut, I made some decisions about the model airfoils. The molded parts of the inboard wings, the outboard wing panels, and the winglets all use scale airfoils with scale dimensions, scale angles and incidences. The strakes and inboard wing panels are molded at the correct angles, so all you would have to do to align the outboard panels is match them up visually... No incidence meter required anywhere in this kit! The outboard (plug-in) wing panels had the scale 3 degrees of total aerodynamic washout built into them when they are CNC cut.

But...

From the start, I expected that there would be "issues" with the canard. The reason for this is simply...Science! The canard on the actual aircraft is barely over 12 inches in chord! ...And, there are "issues" with the actual aircraft, which many Long EZ and Berkut owners have discovered. At one point, John Roncz, an aerodynamic genius working with Burt Rutan, re-designed the canard airfoil for better performance in rain. At 1/3rd scale, this gives a scale canard size just over 4 inches chord. ...And the punchline is that, at that scale, the actual elevator chord is only about 1 inch, and it's supposed to function like a slotted flap..

There is no data I could find concerning these airfoils at the Reynolds numbers I would be flying at. I searched NASA, the Langley Technical Report Server, all the Rutan articles I could find, information from Berkut Engineering, the Selig Airfoil Database, and various other sources.

So, lacking both time and millions for wind tunnel research, I chose to attempt the scale canard anyway. I designed and built a scale canard with the actual airfoil, and the slotted flap geometry. (Results of this are further ahead in this article, when flight testing began.) The molded canard hatch was designed with the idea in mind that I might have to alter the canard later, so I had enough flexibility built in to proceed with the project and solve this later, via flight tests.

|

Interesting Aerodynamic Factoid:

It's been my experience, and most designers agree, that at the scale and airspeeds used in most typical or "sport" modeling, that once the chord of an airfoil goes below approximately 5 inches, it doesn't matter too much what it's shaped like. Notice that most tail parts of this size in kits are simply flat sheet balsa. So, the Berkut-Long EZ scale canard is in this range... |

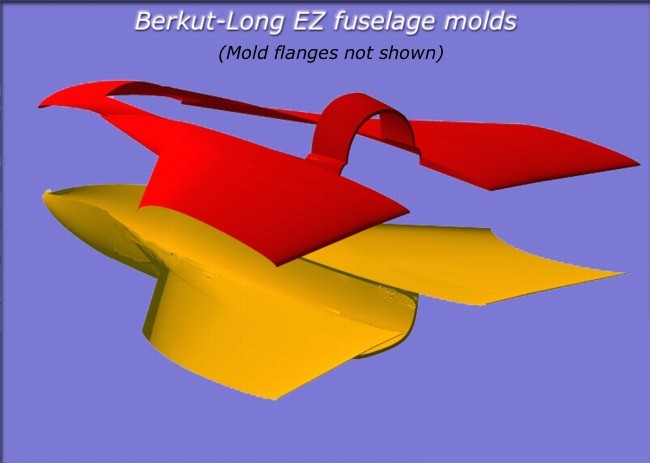

Since the Berkut wing center sections were integral with the fuselage, I decided to make the molds a top/bottom type, rather than left/right. This makes it possible to easily install the spars during production.

The 1/3rd scale Berkut-EZ offered these benefits:

The kit had a very low parts count, and very few steps (compared to a built-up kit) were required to get the model ready for flight. Under time pressure to test the prototypes, I assembled each one in less than a week.

Although large, this model could be transported easily, due to a removable canard, plug-in outer wing panels, and the retractable nose gear. The winglets could be made to be removable too, but I recommended the stronger and more scale-like permanent installation.

I realized that some builders might wish to build a "stock" Long EZ rather than the Berkut variant, so provisions are made in the kit to attach the canopy in one piece, rather than the Berkut's 2-piece "fighter-type" style.

The composite, molded fuselage housed the engine, radio, fuel, and all the structural components, including the main spar, and landing gear. This meant that the fuselage could stand on it's own landing gear during assembly and break-down, eliminating the need for a stand.

The engine compartment was huge, allowing a wide variety of glow and gas engines. Builders would make the engine choice depending on scale detailing and performance needs. I saw no need to use any engine larger than the 2-cycle OS 1.60 FX that I used on the prototypes. It was plenty of power, with a Zinger 18-12 pusher prop.

The retractable nose gear (option) cleaned up the plane considerably, and accepted a variety of gear types, including BVM, Robart and Spring Air.

The large size of the kit allowed servos to be placed in the wing outer panels, simplifying setup and maintenance, and allowed more room in the cockpit area for scale detailing.

A separate, molded, scale-size speed brake was created, and could be installed as an option. (Fun, but not required)

The actual Long EZ and/or Berkut is readily available in most areas, so documenting one for scale competition is easy.

So, with most of the major design details resolved, it was time to cut some parts and start building!

Click the "Construction page one" link below to move on to the model details.