1/6th scale Piaggio "Avanti" P-180

I've built a new (2009) 3D model of the Piaggio "Avanti II" P180, which is now in my 3D catalog, at http://www.mikejamesmedia.com/3d_catalog.html. The information below is from my original work on this plane, beginning in about 1996.

This beautiful aircraft, built by Piaggio of Italy. is a breakthrough of sorts, being almost as fast as many corporate jets, yet much more fuel efficient, due to the use of turbine driven 5-bladed pusher propellers and many other many unique design features. The RC kit was planned to be fully molded, including the wings and tail surfaces, and molded-in panel lines, gear doors, etc..

This aircraft features a three lifting surface design, and very low drag shapes on every part of the aircraft. Even the engine nacelles are area ruled, for low drag. As you might guess from the appearance, it began as a joint project between Piaggio and Lear. The foreplanes function as a third lifting surface, and include flaps. The inboard section of the wing includes slotted flaps, and the outboard section includes slotted Fowler flaps. Pitch is controlled by the elevators on the horizontal stabilizer, which is an inverted airfoil, and flies at a "no load" condition in cruise. The fuselage is also a lifting body, with great laminar flow characteristics. It includes the Lear-style ventral stabilizers, which create almost no drag at cruise, but force a nose-down condition as the aircraft gets close to the stall. These things combined allow for the wings to be 20% smaller than they would otherwise be.

I decided that this wouldn't be a practical scale model unless it was at least 1/6th scale, which makes it LARGE. Still, this will have to be built lightly to be effective. Although capable of supporting power in the .60 2-cycle range, electric power would be a good choice too.

Here are the specs for the model.

|

Overall Length |

94.54 inches |

|

Main Wing Span |

94.50 inches (Area 688.84 inches) |

|

Foreplane Span |

22 inches (Area 81.86 inches) |

|

Horizontal Stabilizer Span |

29 inches |

|

Scale Propeller Diameter |

14 inches |

|

Wing loading (includes forplanes) at 15 lbs. |

about 36 ounces per square foot |

The weight estimate of 15 pounds is close, figured using two OS .46 engines. The fuselage is HUGE, (typical cross section of 12 to 13 inches at widest point) but there's good news too. All the main structural components of this aircraft very intelligently meet at one point, which is at the fuselage/wing intersection. That means the rest of the fuselage can be very lightly built, and it should fly well.

NOTE:

I've left the rest of this article as I originally wrote it, in about 1998. But, this model never went any further than what you see on this page. Due to labor costs, molds were never produced, and no other parts were ever made. I have no kits, plans, or drawings whatsoever to sell, aside from the 3D model. (link at the top of this page)

The actual P180

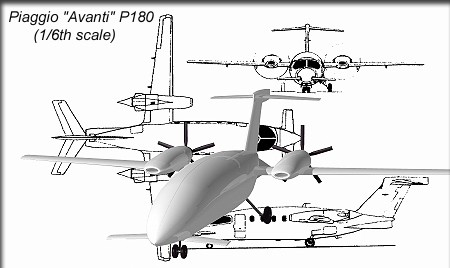

With the help of some great documentation, I made a CAD model of the P180.

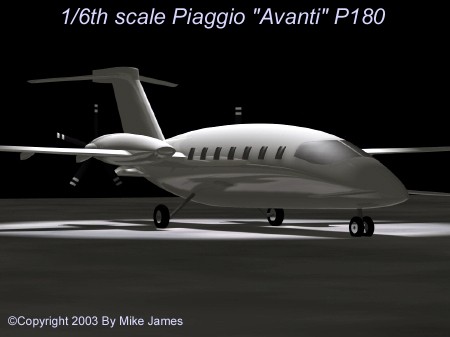

My CAD model of the P180

There are more images of this aircraft, showing my design process, on the 3D Design Techniques page. Two engineers from Piaggio have flown a 1/7th scale model and had success, although it flew "hot". Here are some photos of my progress so far:

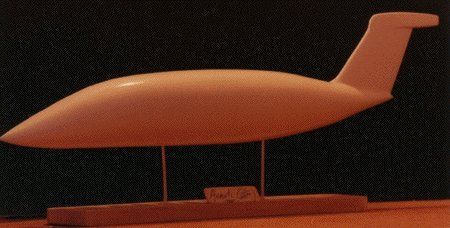

To help me visualize construction, I made this 1/20th scale model first.

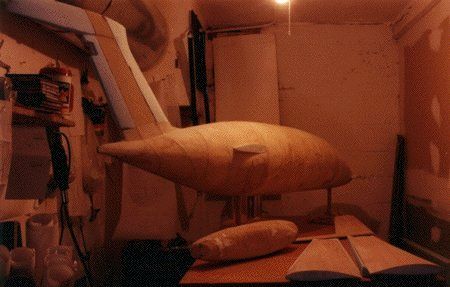

Plugs are under way, and all flying surfaces have been completed, since I'll need them to produce fillets, etc.. The large object on the table near the wings is the plug for the engine nacelles.

Here's the 96 inch fuselage plug primed for the first time. (weighs about 75 pounds!) The 4 supports you see in the fuselage are cut up broomstick handles. As you might guess, each step in this process requires a lot of epoxy or primer, or whatever. That's why this is a long-term project for me. It takes a while for something big!

Details on how I made this plug are on the Making Plugs For Fiberglass Molds...Differently page. It's pretty much standard procedure for me now to use the computer as part of my design and visualization process. Below are some computer-generated images I made in the design of this model.

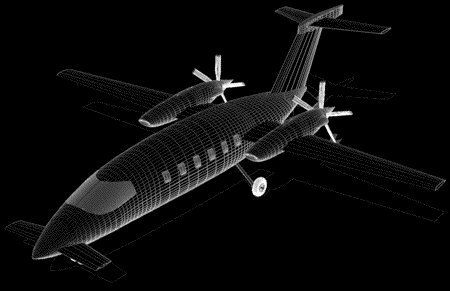

The 3D model library at Digmation was previously operated by Viewpoint Digital. When we first started to process the model through Viewpoint's "Quality Assurance" profile, the DXF model had 160,000 polygons. It was a very accurate scale exterior model, as you can see in this wireframe view.

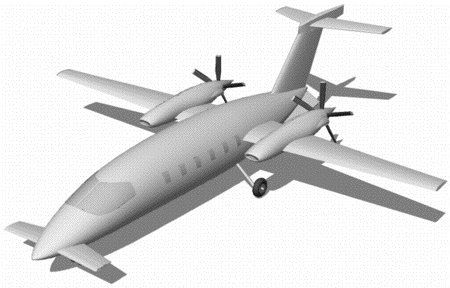

Here's the same model in it's rendered form.

Here's a some shots of what I hope it eventually looks like.